Thermal deburring

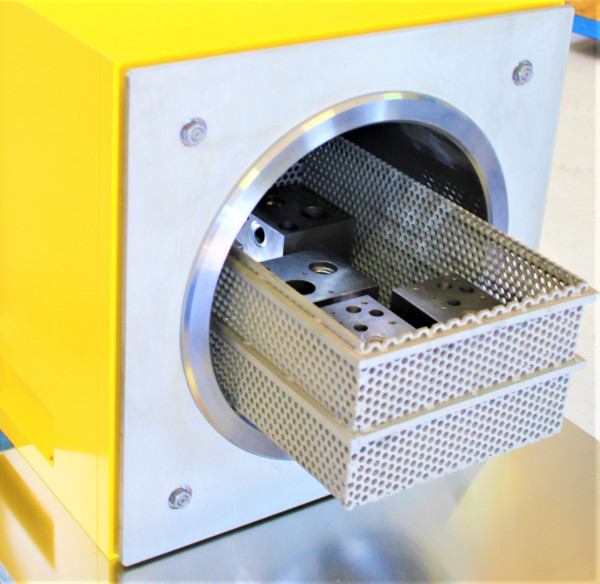

The work pieces are placed into a pressure chamber that is filled with a gas mixture and then ignition is initiated. The gases that can be used for this process are hydrogen, methane and natural gas.

The work pieces are placed into a pressure chamber that is filled with a gas mixture and then ignition is initiated. The gases that can be used for this process are hydrogen, methane and natural gas.

When the gas mixture is heated up temperature rises up to 2.500 - 3.000 C within several miliseconds. This causes heat cummulation which burns out the burrs. The resulting oxide is precipitated on the surface of the work piece.

Work piece before and after the process of thermal deburring

The element to be thermally deburred must be clean, dry and deoiled. Residues of oxides formed in the process can be removed by cleaning in acidic or neutral detergents.

No movies