WIR G-BOX

The machine used mainly for parts after shaping or extrusion i mass production. The multi-operation machine (cleaning + rinsing + drying) allows for better cleaning effects required before painting, assembly, packaging, etc. The parts are sprayed from all sides. During the cycle, the basket rotates or rocks around horizontal axis. Its maximum load is 1000 kg.

No movies

WIR 6H/6C, WIR 4H

The elements that are supposed to be washed are placed in a perforated drum (WIR6C) or in a cuboidal basket (WIR 4H) rotating in the horizontal axis. Such solution ensures good results even at complicated geometry of the elements and in case of the elements with threaded holes and blind holes. Multifunctional cleaning machine (cleaning + rinsing + drying) allows for reaching higher cleanliness level required before painting, asembly or packing.

No movies

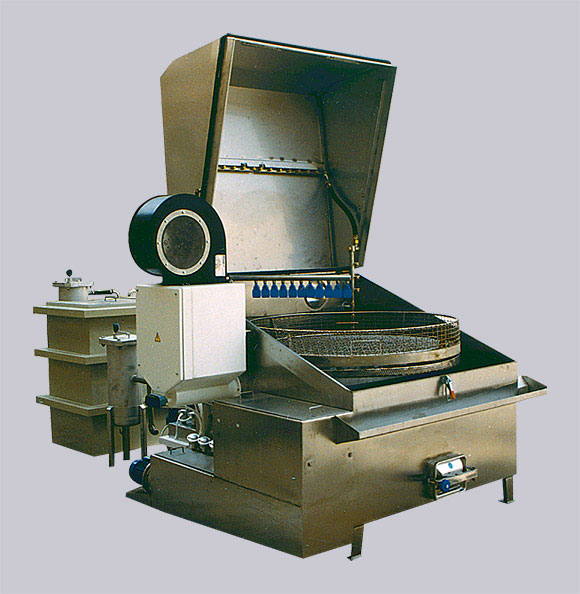

KOMBI Cleaning machine

This machine allows for degreasing the parts of the weight up to 1000 kg using spraying cleaning, rinsing and drying with hot air.

No movies

CI5

The machine is characterized by a small construction and can be used for degreasing and cleaning of fine elements or small batches.

No movies

MCL/MCD

This machine type is designed for industrial cleaning at production, servicing and regenrration. Cleaning machine MCL or MCD allows for several steps of the operation: cleaning - rinsing (second rinsing) - drying, which results in better cleaning effects required before processes such as: painting, assembly, packing etc.

No movies

DC3

This machine type is designed for industrial cleaning at production, servicing and regenrration. Cleaning machine DC3 allows for several steps of the operation: cleaning - rinsing (second rinsing) - drying, which results in better cleaning effects required before processes such as: painting, assembly, packing etc. Maximum load weight is up to 250 kg.

Exemplary element:

Oil mist filter: before and after cleaning process. This is the effect after ca. 10 minute degreasing cycle.

No movies

WIP, WIK

Cleaning machines WIK or WIP allow for several steps of the operation: cleaning - rinsing (second rinsing) - drying, which results in better cleaning effects required before processes such as: painting, assembly, packing etc. They are perfect for degreasing of huge, heavy parts. The maximum load is up to 1500 kg.

No movies

ATOLL, ATOLL K2, ATOLL mini

The machine allows for various technological processes, such as cleaning and several step rinsing with the use of immersion or spraying mathod. The machine can be equipped with ultrasounds,turbulences, hot air drying as well as vaccum drying. Atoll machines are used and recommended by our customers from aircraft industry.

No movies

Special cleaning systems

Ultrasonic lines, simple workshop washers, combined systems - manual and automatic modes in one device. Special solutions for atypical elements.

No movies

Tunnel machines

Tunnel machine allows for cleaning process of the elements of various shapes and weight. The elements transported on the transporting belt pass through the following zones: cleaning + rinsing + drying.

No movies

Demineralizers

ION EXCHANGE RESINS

Demineralizer systems with ion exchange resins are mainly used to produce deionized water or in the closed-loop filtration of industrial cleaning water. Ineed, in adition to producing pure deionized water, demineralization plants significantly reduce water consumption in cleaning process while ensuring optimal quality of reused water.

The ion exchange action of the resins removes ions present in the water to achieve an output conductivity of less than 20 μS/cm.

Ion exchange resins are composed of a polymer matrix in which free ions available for exchange are trapped or incorporated. The resins can retain an amount of ions equal to their exchange capacity; once this limit has been reached, they have to be regenerated.

SAITA has been producing demineralization systems used in multiple industrial applications for more than 40 years.

Appllications

Recycling demineralizers

Closed-loop filtration with exhcange resins in the cleaning steps significantly reduces water consumption and improves cleaning quality.

Demineralized water production

Demineralization systems with ion-exchange resins to produce pure deionized water from city or well water.

Selective ion removal

Special selective resins for specific types of ions. Typical uses are on the output of water treatment plants to remove dissolved metals traces before sewer drain.

Special applications

Food grade ion exchange resins for the decolorization and demineralization of fruit juices and liquid solutions for the Food and Beverage industry.

Specifications

SAITA demineralization systems are modular and installed on a tubular stainless steel skid. Featuring a feed pump, an activated carbon filter, a cationic resin filter and an anionic resin filter.

Filters are fiberglass vessels with inner PE liner complete with upper diffuser and lower drainage. Hydropneumatic valves (multi-way or single) are installed on each filter for washing, backwashing and regeneration. The operating logic and management of the washing and regeneration stages is automated and controlled by an electronic programmer.

The dosing and dilution of acid and alkaline solutions, for resin's regeneration, are flushed through the filters by a venturi ejector. Suction flows are regulated by manual or automatic valves and variable are flow meters. The electrical conductivity of the deionized water produced is monitored by digital instrument with a detection cell.

Sectors

- Electroplating

- Powder coating

- Aluminium anodizing

- Ultrasonic cleaning

- Pharmaceutical

- Chemical industry

- Steam generators

- Electronic and semiconductors

- Food&Beverage

- Cataphoresis and electrophoresis

Advantages

- Recirculation of rinse water

- Water savings

- Highly pure deionized water

- Resins regeneration

- Resin durability > 5 years

- Selective ion removal

Series

CD Series

Standard three-column filter demineralizers consisting of: recirculation pump, activated carbon filter, strong cationic resin filter and strong anionic resin filter.

LM Series

Demineralizers for producing ultra-pure demineralized water < 0,5 μS/cm with generable and non-regenerable mixed-bed resins.

CK Series

Decationizers to recirculate mildly alkaline rinse water using weak cationic resin and complete with quartz sand or activated carbon pre-filtration.

CDD Series

Filtration of mildly acidic rinse water, demineralizers with four filtration columns and double columns of anionic resins: stron and weak.

Duplex Series

Double line demineralizers used to ensure continuous 24H production and recirculation of demineralized water.

Optionals:

- Automation with industrial PLC

- Remote control on PC, tablet or mobile

- Pumps with inverter

- Microfiltration

- Analogic flow meters

- UV sterilization

- Storage tanks

- Industry 4.0 Ready

No movies